CNC Punching

Computer numerically controlled (CNC) punching is a sheet metal manufacturing process that is carried out by CNC punch presses. The CNC punching machine is basically programmed to move a sheet of metal in an x and y direction so as to accurately position the sheet under the machine’s punching ram ready to punch a hole or form.

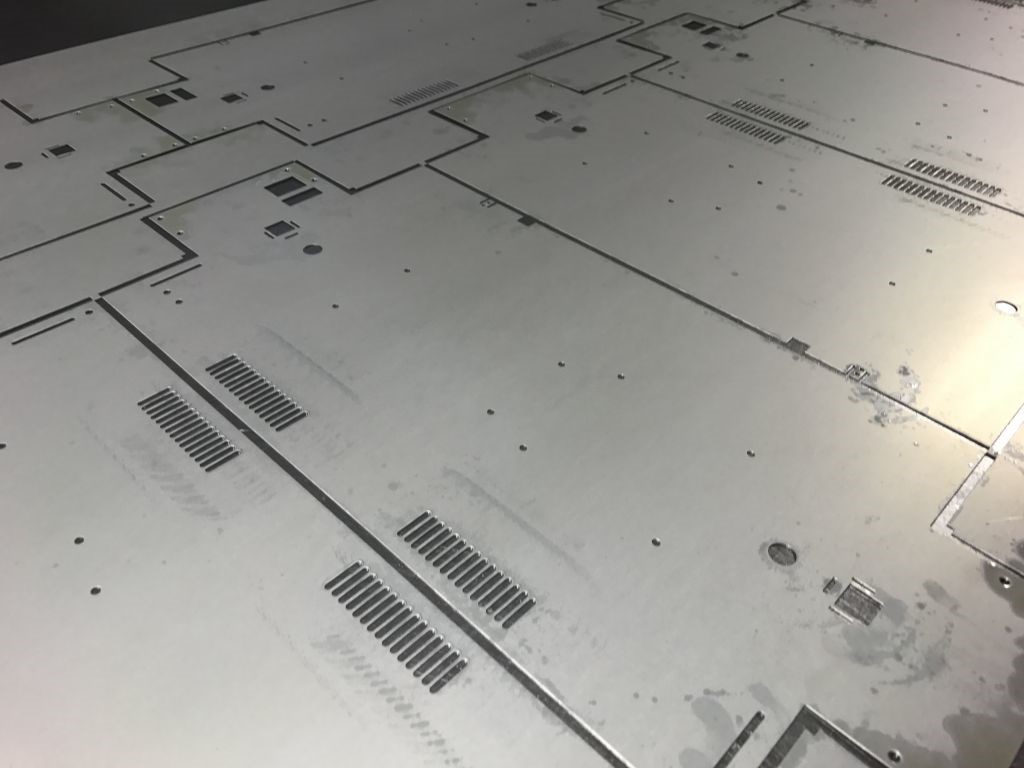

The processing for our CNC punch presses is 0.5mm to 3mm thick in a range of materials including steel, Zintec, galv, stainless steel and aluminium. The choice of hole punched from our massive collection of punch and dies can be as simple as a circle to a square right through to special shapes to suit a specific cut out design. By using a combination of single hits and overlapping geometries, complex sheet metal component shapes can be achieved, as well as multi hits we can produce perforated sheet design. our machine can also punch 3D forms such as dimples, taptite screw thread plunges, and electrical knockouts etc on either side of the sheet, which are often employed in sheet metal enclosure design. The instruction to drive the machine to create the desired component geometry is known as the CNC program.